InWin Factory Tour Computex Part 3

Peter Donnell / 10 years ago

Welcome back to our tour of the InWin factory in Taiwan, we’ve already looked at how InWin create their plastic chassis moulds and metal components in the last two parts of the tour. Now we move on to some of the finer details in the production line.

As you can see in the picture above, the panels are ran through a special spray painting machine which gives them the first part of the final finish. This is done in a sealed room and protective breathing gear must be worn while working here.

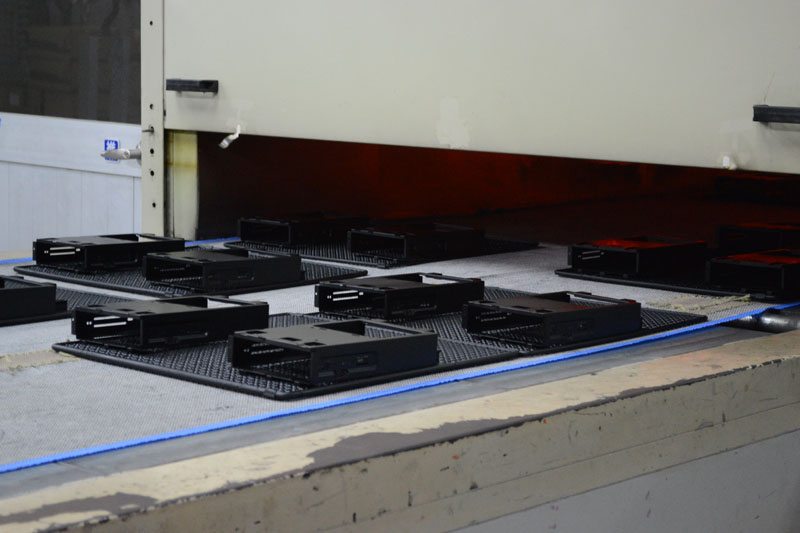

Once sprayed, the panels are laid out on trays to cool and dry, making them ready for the next step in production.

Some of the panels are also run through an oven to help seal and dry the paint work, and given that Taiwan is already a hot place, you can imagine it’s pretty hot here, we suspected it was around 45c and we were only there for a few minutes.

Our favourite feature of the factory wasn’t the cool products we saw, it was these air conditioning units on the wall, we spent way longer than InWin would have liked staring at this while enjoying the cool air it provided.

The final details of the builds require a more hands on approach, printing techniques are used to put logos and other designs onto chassis panels, each one done one at a time.

Smaller components require bigger production lines, allowing finer details and cleaning of parts such as the 5.25″ drive bay covers, buttons and front panels.

Once all the parts are complete, having gone through their extensive manufacturing processes, they’re bolted together. Here you can see a team of people screwing together the H-Frame mini.

A final few screws and a clean, they’re wrapped and placed in their boxes.

Leaving the final product ready to go to retail.

One of the super computers used to run the production lines, nothing major, but we love a good giggle at old computers.

Here you can see the two banks of tooling machines we saw in part 2, it’s a huge line up of machines at full speed we find that InWin can turn out around 1 million cases a month here!

All the products are then stacked up neatly, ready to ship out around the world for resale.

And here we see InWin loading up a fresh batch of the finished products. All of which were designed, manufactured and dispatched from this factory. From the smallest parts to the biggest panels, InWin do it all themselves and we’re very grateful they let us in to see how it all comes together.